Difference between revisions of "Building the Mower"

m |

|||

| Line 119: | Line 119: | ||

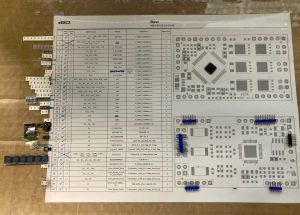

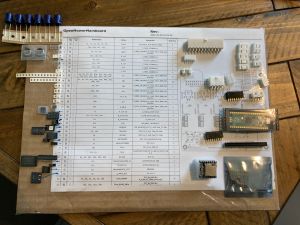

Get Organized: Before you start assembling and soldering the PCB's, it's recommended to organize all of your parts. One method is to print off the iBOM.html file, tape it to a piece of cardboard, and then put double sided tape next to each line item. Only take out the parts/components you need for (1) xESC at a time, or the parts for the Mainboard, then place them on the double sided tape. Here are a couple of examples: | Get Organized: Before you start assembling and soldering the PCB's, it's recommended to organize all of your parts. One method is to print off the iBOM.html file, tape it to a piece of cardboard, and then put double sided tape next to each line item. Only take out the parts/components you need for (1) xESC at a time, or the parts for the Mainboard, then place them on the double sided tape. Here are a couple of examples: | ||

[[File:XESC-Parts-on-iBOM-wiki.jpg|thumb|Organize xESC components.]] | [[File:XESC-Parts-on-iBOM-wiki.jpg|thumb|Organize xESC components.|left]] | ||

[[File:MainBoard-Parts-on-iBOM-wiki.jpg|thumb|Organize MainBoard components.]] | [[File:MainBoard-Parts-on-iBOM-wiki.jpg|thumb|Organize MainBoard components.]] | ||

| Line 161: | Line 151: | ||

==Setup and test== | == Setup and test== | ||

Revision as of 15:41, 8 July 2022

Welcome to the OpenMower Building guide!

Note: This WIKI was only just started on 2022-04-22, but are actively working on filling it up and making a good documentation for the new builders out there!

Warning

Please note that this project currently is in a very early stage! So don't go buying stuff right away! You will need to order and solder your own boards, since there are no assembled boards for sale yet.

Please make sure that you're actually allowed to build this device in your area. There may be laws / patents prohibiting you of doing so!

Please just be responsible and if you're not sure what you're doing, please don't do anything.

BTW the warranty of your brand new mower will obviously be void as soon as you modify it in any way, so be aware.

Intro

Below you can find an overview of the major parts and components in the OpenMower.

There is a also another page with a Builder Road Map that gives guide to how to go about building your own OpenMower project.

Bill OF Materials

| Name | Description | Optional | Availability | Quantity Required | Source Link 1 | Alternate Source |

|---|---|---|---|---|---|---|

| Mower (Yardforce Classic 500) | Base building block | Off the shelf | 1 | https://amzn.to/3NWgIxk | Note: Earlier, we had a reference to myrobotcenter. However, they have gone into reconstruction, so be aware of that vendor! | |

| OpenMower Mainboard | The core of the new electronics. | Custom | 1 | Components Octopart BOM | WIP | |

| xESC | Motor drivers | Custom | 3 | Components Octoparts BOM:

- STM32 |

WIP | |

| Raspebrry Pi 4 | The brain of the robot. Also used to send RTK correction data from the base station.

|

Off the shelf | 2 | https://rpilocator.com/?cat=PI4&instock | WIP | |

| Ardusimple RTK2B GPS | Positioning system for the bot | Off the shelf | 2 | https://www.ardusimple.com/product/simplertk2b-basic-starter-kit-ip65/ | https://www.ardusimple.com/product/simplertk2b-basic-starter-kit-ip65/ | |

| Raspberry Pi Pico | Microcontroller talking to peripherals, soldered to the OpenMower mainboard | Off the shelf | 1 | Widely available | ||

| MPU 9250 | 9-axis accelerometer sitting on Mainboard allowing for direction through compass and dead reckoning of movement between GPS updates. | Off the shelf | 1 | You may need to shop around, corresponds to this one | https://aliexpress.com/item/1005003056348525.html

https://aliexpress.com/item/32787237588.html | |

| 3D printed brackets | To hold the GPS inside the bot | Custom | 1 | https://www.printables.com/fr/model/175826-openmower-gps-mount-for-yardforce-classic-500 | WIP | |

| SMA Angle Adapter | Needed to connect the GPS without bending the wire too much | Off the shelf | 1 | https://amzn.to/3K913b1 | WIP | |

| CC/CV Step Down module | As charger for the docking station | Off the shelf | 1 | https://amzn.to/3NUdRVL | WIP | |

| Docking Station Adapter PCB | A PCB to hold the module in place. | Custom | 1 | WIP | WIP | |

| GPS PCB | A ground plane PCB to improve GPS reception | Custom | 1 | WIP | WIP | |

| USB Angle Adapter | If you want to use the Classic 500's USB port | YES | Off the shelf | 1 | https://amzn.to/3ukNAIj | WIP |

Building the bot

Once you have gathered up all of the parts, components, tools, and have a set of PCB's, it's time to start building the OpenMower Robot.

First thing first, watch all of Clemen's Youtube video's, and then watch them again. They contain a Treasure Trove of information and should be used as a reference. https://youtu.be/_bImqD-pQSA

Get Organized: Before you start assembling and soldering the PCB's, it's recommended to organize all of your parts. One method is to print off the iBOM.html file, tape it to a piece of cardboard, and then put double sided tape next to each line item. Only take out the parts/components you need for (1) xESC at a time, or the parts for the Mainboard, then place them on the double sided tape. Here are a couple of examples:

Now you want to apply solder paste to your PCB, BUT, before you apply solder paste to your PCB's with a stencil, make sure to wipe down both the PCB and the stencil with isopropanol alcohol to clean the surface, this helps more than you would think. Once the IPA has evaporated, align your stencil on top of the PCB, and use masking tape or painters tape on one side to act as a hinge, so after you apply the solder paste, you can carefully remove the stencil. Please reference Clemen's Youtube video for soldering: https://youtu.be/Y16kbAK3vaU

Here is an example photo of a PCB after applying the solder paste:

And here is a video inspecting the PCB after placing the components onto the solder paste / PCB with tweezers: